About Valio

Valio Ltd. is Finland’s leading dairy and food company, known worldwide for its high-quality products and innovation. The company holds more than 350 patents and is recognized as a pioneer in both product development and production technologies. With strict quality and traceability requirements, Valio continuously develops its production in cooperation with its vendors, selecting the best technologies for each need.

Challenges

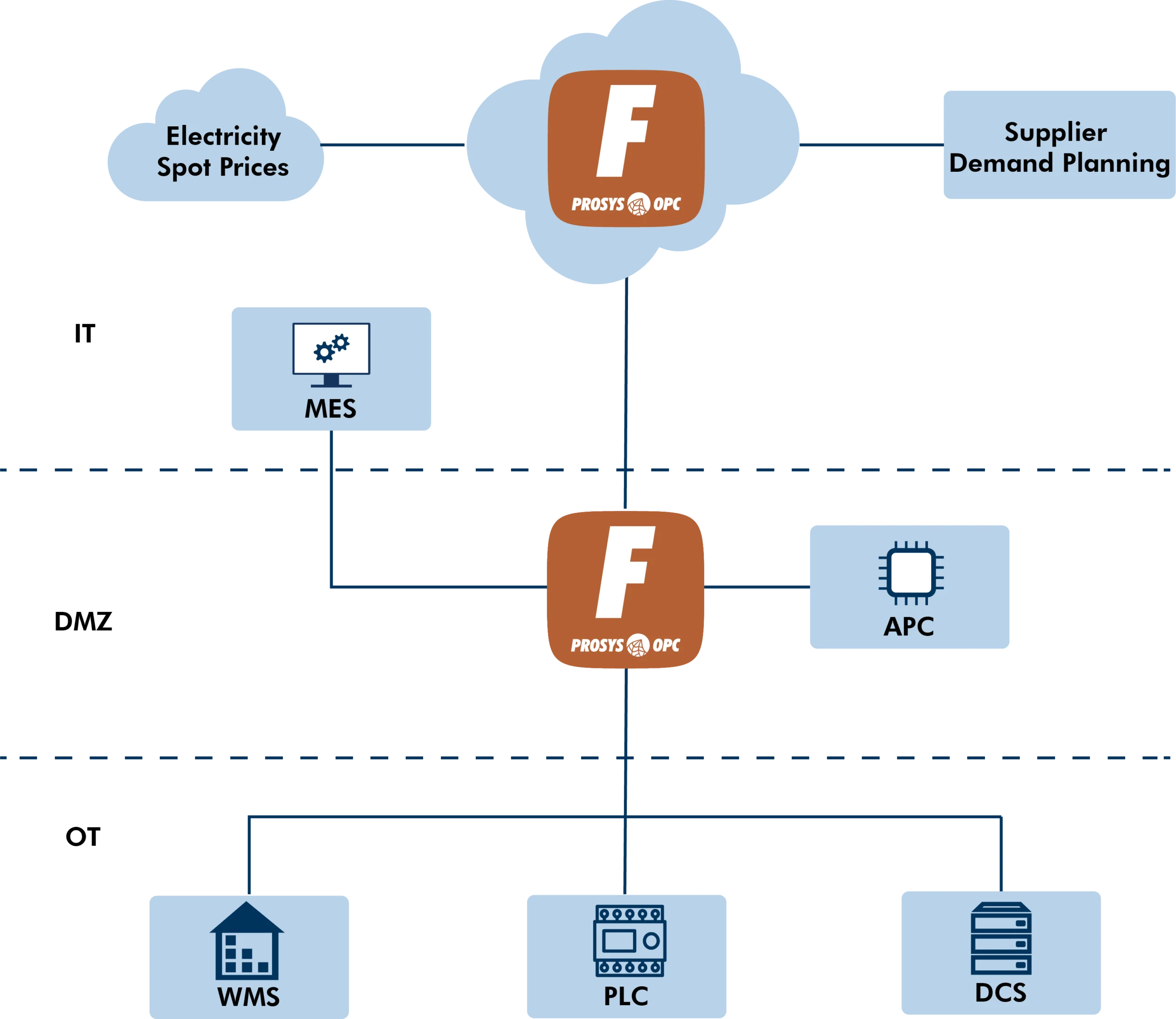

Valio’s dairy plants operate with a mix of operational technology (OT), from distributed control systems (DCS) and programmable logic controllers (PLC) to embedded controllers and PC-based solutions. These diverse systems needed to communicate reliably and securely with Valio’s manufacturing execution system (MES), Advanced Process Control (APC) and IT infrastructure.

Historically, this integration relied heavily on custom-made software and point-to-point connections. While effective in the short term, it created complexity, made scaling difficult, and hindered the introduction of new solutions, such as advanced analytics and cloud integration. Valio needed a more standardized, secure, and future-proof approach to connect automation with IT systems and the cloud.

Solution for Secure IT/OT Integration

Valio chose Prosys OPC UA Forge as the integration layer between automation, MES, and Azure cloud services. Within one year, the project was executed in 12 production sites, including planning, installation, configuration and documentation. Today, Forge enables standardized, secure, and real-time communication within Valio’s production systems, while minimizing the need for any custom interfaces.

Key aspects of the Forge setup include:

- Simplified configuration and scalability, replacing multiple custom software solutions with one centrally managed platform, enabling significant savings in maintenance cost.

- Unified integrationof automation systems with MES and IT, using OPC UA standard-based communication.

- Cloud connectivity, enabling the use of Azure for data storage, distribution, analytics, and advanced services.

Cloud-Enabled Supply Chains and Optimization

While the site level implementation allows data to flow seamlessly between shop-floor systems and higher-level applications, Valio’s performance and supply chain optimization is boosted by Forge running in the cloud. This enables loading external data, such as electricity spot prices, directly into Valio’s systems to be used in production planning and control. The other way around, suppliers can be provided with real-time visibility into the necessary OT data, helping them to autofill and perform real-time demand planning.

The Prosys OPC UA Forge deployment project was carried out exactly according to plan, both in terms of costs and schedules. During the co-operation we have found out that Prosys OPC UA Forge is a versatile product, capable of executing secure IT/OT integration in all our production sites and extending to cloud-based systems. We always prefer forward-looking and reliable suppliers that properly understand production environments, and Prosys OPC fully meets our requirements.

Mika Puustinen

Service Manager, Valio

Future Outlook

With Prosys OPC UA Forge as the foundation, Valio is well-positioned to expand its Industry 4.0 initiatives. The standardized platform not only supports current automation and MES integration but also paves the way for new applications, such as AI-driven analytics, sustainability tracking, and tighter supplier collaboration. By bridging automation and IT through Forge, Valio has built a robust and flexible integration layer that will continue to support innovation, efficiency, and quality in its production for years to come.