From MTConnect to OPC UA: Future-Proof CNC Data Collection with Forge

i-GuSystem

About i-GuSystem

i-GuSystem Ltd. is a Finnish company specializing in industrial production digitalization and efficiency improvement, holding a leading position in its niche, CNC machine program transfer and production data acquisition.

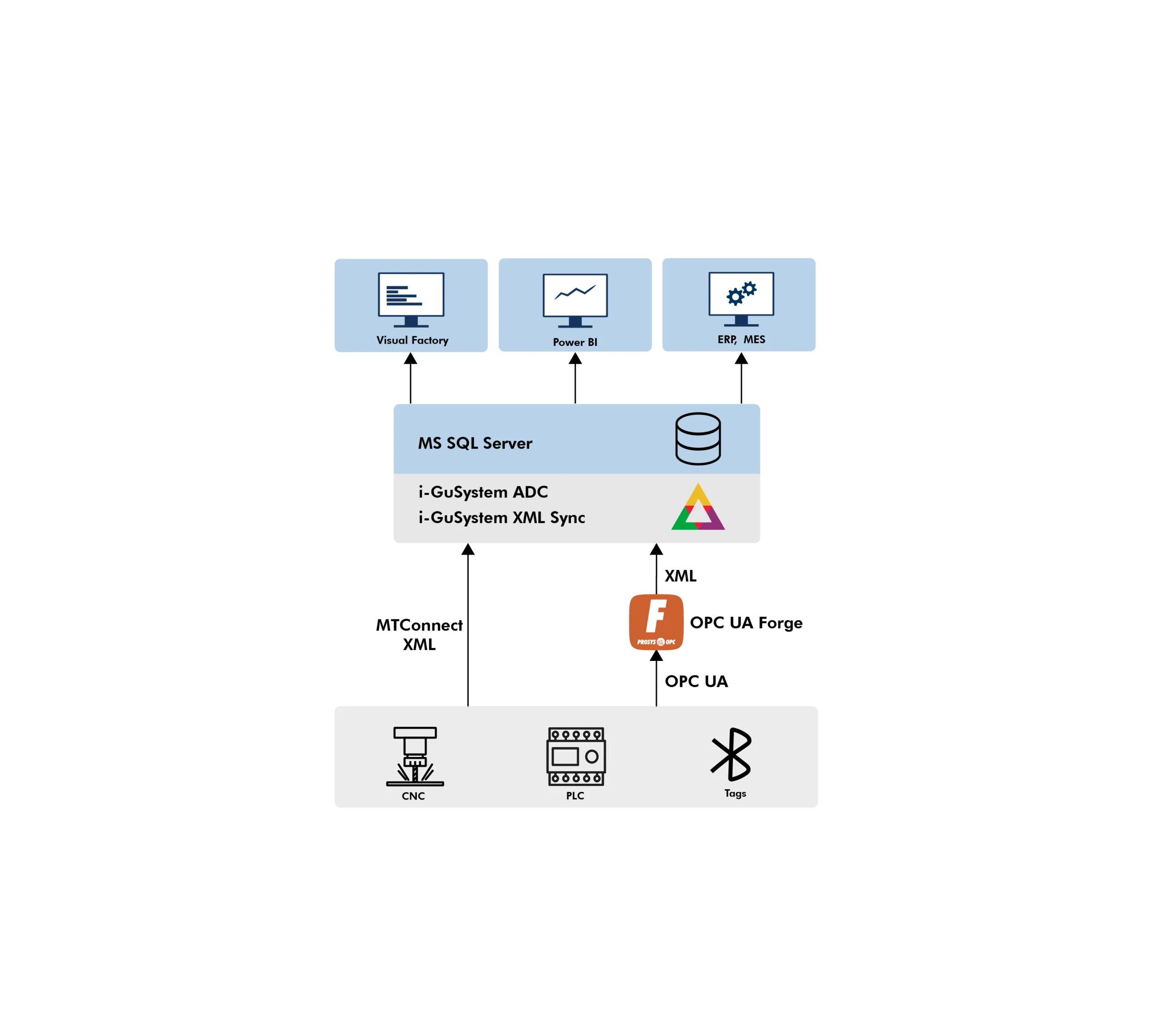

The company delivers solutions for CNC program transfer (DNC), machine status and production data collection (ADC), and data management. Its in-house products include MTConnect and PLC adapters, the iguXMLsync software for compiling and transferring data to databases, and complete installation services. i-GuSystem also offers the VisualFactory turn-key solution with exclusive sales rights in Finland, along with custom integrations to third-party systems.

i-GuSystem is particularly known for its ability to read production equipment directly without additional sensors, enabling more accurate and efficient data collection. Solutions support both modern OPC UA and MTConnect connections, as well as PLC- and wireless tag-based data acquisition for older machines.

The company provides exceptional, hands-on expertise in connecting machines, from the oldest RS232 interfaces to the latest high-end controls, and has connected more CNC machines in Finland than anyone else. This deep know-how, combined with proven reliability of its solutions, has built i-GuSystem’s strong reputation both domestically and in international projects.

From MTConnect to OPC UA: Preparing for the Future of Machine Data

i-GuSystem has long relied on MTConnect as its primary interface for extracting data from machine tools. Recognizing the increasing prevalence of modern equipment featuring OPC UA servers, either pre-installed or as optional add-ons, the company acknowledged the need to adapt to this emerging standard.

This shift became particularly pressing when one of i-GuSystem’s key customers, a prominent international machine builder, acquired a new Liebherr CNC machine equipped with Siemens 840D and an OPC UA server. This development prompted i-GuSystem to accelerate its transition to OPC UA technology.

In response to this growing demand, i-GuSystem began searching for an expert who could assist in accessing and transforming OPC UA data efficiently, ensuring continued compatibility with existing tools and systems. A core requirement was the ability to deliver machine data in XML format, which was essential for maintaining seamless integration across the data pipeline.

The Solution: Prosys OPC UA Forge as a Future-Proof Integration Layer

After a thorough evaluation of available options, i-GuSystem selected Prosys OPC UA Forge due to its ability to directly connect to OPC UA servers and output data in the required XML format. This solution ensured full compatibility with existing iguXMLsync software, which handles downstream processing, storage, and integration with various systems, including VisualFactory, MES, MQTT-based cloud services such as Azure, and Power BI dashboards.

Unlike other solutions, which would have required separate tools for OPC UA data collection and database integration, introducing unnecessary complexity and risk, Forge offered a unified, robust, and cost-effective path forward, positioning i-GuSystem for continued success in the evolving landscape of machine data management.

Seamless Experience and Quick Deployment

i-GuSystem received the Forge installation package and completed the first deployment on-site at their customer’s facility in just two hours, from arrival to having the new machine connected and data flowing in the desired format. The CNC machine had already been cabled and tested, but the speed and ease of integration exceeded expectations.

A few quick support calls to Prosys clarified minor configuration details, and the system has since continued operating reliably. Forge now plays a key role in ensuring compatibility across new machine tools, reducing engineering overhead and making i-GuSystem’s solutions even more scalable and future-ready.

“I expected the first install might take a full day, maybe two. I left the site in just two hours, everything working as planned. That’s rare in this business.”

Jouni Myllys

CEO, i-GuSystem Oy