Advanced Process Control [APC] System Benefits from the New OPC UA Technology

Summary

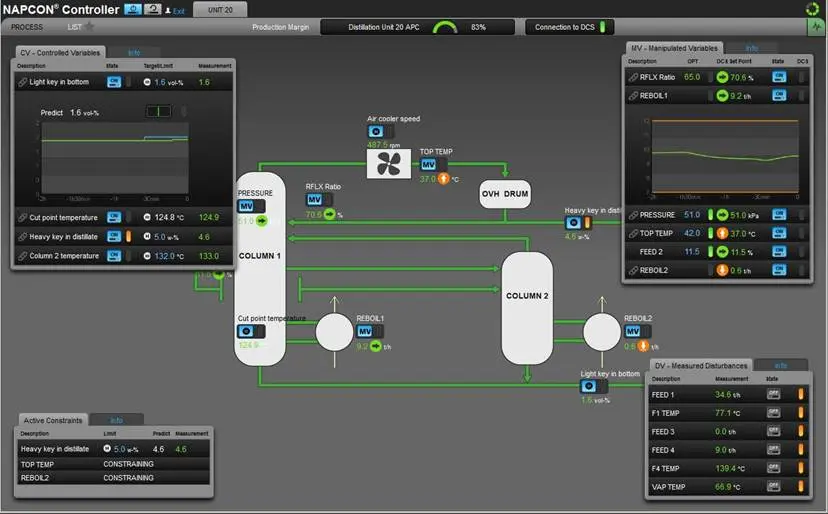

Prosys OPC has collaborated with Neste to add the new OPC UA communication protocol to the NAPCON Informer real-time process database. NAPCON Controller is Neste’s proprietary advanced control technology, which uses a model-based multivariable multistep technology, including adaptation, disturbance estimation, online calculations, general constraint handling, online analyzer support, and recipe integration. NAPCON Controller was initially developed to optimize the control of polyolefin reactors and polymer product properties and was rapidly generalized for oil refining and petrochemical plants. It has proved valuable in improving plant operation management and substantially improved product uniformity, yield, throughput, and on-spec production. NAPCON software products utilize an integrated NAPCON real-time database and historian, with several external interfaces to other systems.

Agile methods for customer value

The initial assignment from Neste was to develop an OPC UA server based on .NET technology to enable the use of the NAPCON database via OPC UA. Agile methods were used in the project to maximize the customer value for each iteration. After a feasibility study and a complete system design phase, iterative development began. Throughout the development of the software, Prosys OPC and Neste held regular review sessions to examine recent developments and focus on next-step improvements. This way, at each step, the features most valuable to the customer were added to the system.

Robust OPC UA connectivity

For example, the developed OPC UA capabilities are used to exchange data between the NAPCON real-time database and a DCS or PLC. NAPCON features the entire OPC UA server and client capabilities to suit any solution perfectly. The new OPC UA software integrates with existing solutions, and special care has been taken to minimize the need for manual configuration, which has been seen as the main reason for faulty configurations. A special configuration utility was developed to address the issue.

OPC UA offers NAPCON an improved connectivity technology to be used in the various external connections. OPC UA also enables application design improvements by providing a communication protocol that can be used for internal communications between different application modules. Some of the benefits of OPC UA include more accessible and more flexible deployment to different computer and network environments (network firewall configurations, for instance), secure communications, and a unified interface and information model for current data values, alarms, commands, and references between data items.

Flexible user interfaces

Collaboration between Prosys OPC and Neste continues to develop the system further on many fronts.

An example of a new OPC UA related innovation has been the development of browser-based user interfaces for the system. These user interfaces can be used either as a stand-alone HMI or in conjunction with a DCS HMI, where they can supplement existing operator displays. Latest web technologies, such as HTML5 and Node.js, are used to deliver web displays that combine real-time data, history trends, and alarm data.

Another new development is the use of automatically generated OPC UA enabled simulator displays. The displays fetch data from the NAPCON Simulator via OPC UA while providing the look and feel of the simulated system. Using OPC UA communications and code generation allows the cost-efficient upkeep of many simulation displays used for plant operator training.

Prosys OPC provides us with flexible, highly productive expert resources. They have innovative ideas, top technical skills and the required understanding of our application area – the company has proven to be an added-value partner in our systems development.

Andreas Frejborg

Manager, Industrial ICT, Neste

Training Simulator System Enhanced with OPC UA Integration

Summary

Neste wanted to expand its NAPCON® Simulator – training simulator system with hard control and alarm switches. NAPCON® Informer process database features full OPC UA capabilities, so OPC UA was a natural choice for integrating the switches into the system. OPC UA guarantees reliable data communication and easy connectivity and supports future expansions to the system.

Simulator room switch integration

Prosys OPC provided the system as a turnkey solution, including everything from configuring and installing the Beckhoff embedded PC/PLCs on-site to developing the software for the project. First a prototype of the software and hardware was provided, and when it was found functional, the installation of the full system commenced. The project utilized agile methods and close co-operation in creating the system according to the final requirements of Neste.

OPC UA integration for the system was implemented using Beckhoff PC/PLC hardware and TwinCAT PLC programming environment according to the specifications of Neste, including an embedded OPC UA server for connectivity. It was possible to use the off-the-shelf Beckhoff OPC UA server for accessing the system, minimizing the configuration work for the project. The OPC UA server enabled Neste to access and control switches easily, creating the needed functionality for the simulator room.

Prosys OPC showed flexibility and an expert attitude throughout the project. The system and resources were provided as requested.

Jyri Lindholm

Head of Automation Technology, Neste