24/7 Web Quality Inspection

The Unified Valmet Process and Quality Vision System

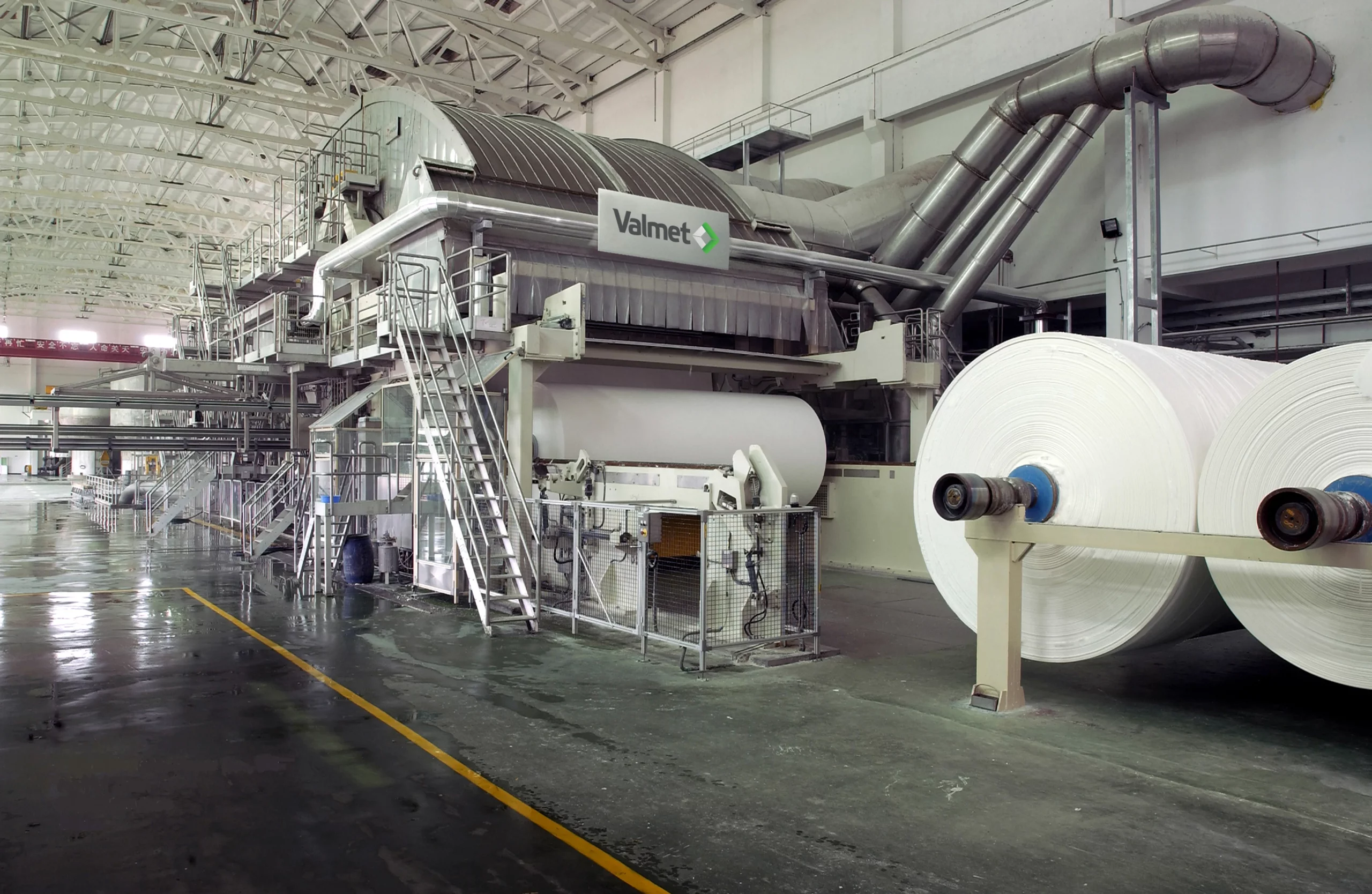

Valmet Process and Quality Vision systems are used for web quality inspection and web break analysis. The system has been applied to paper machines, off-machine coating lines, multiply coated board processes, winders, tissue machines and plastic extrusion processes.

The unified Valmet Process and Quality Vision system is a multi-functional tool for analyzing the origins of breaks and defining the source of coarse or very fine and complex web faults that do not necessarily cause breaks but have to be eliminated before they become customer problems. Thus, the system has a dual purpose: to improve web runnability and to help the mill to ship the best fault-free customer quality.

In addition to the main camera installation, which provides data for the advanced image analysis, the system also integrates with different automation systems. For this purpose Prosys OPC developed an automation system link for the Valmet Process and Quality Vision system, using OPC communications.

OPC for Interoperability

The OPC module developed for Valmet is an independent part of the system, communicating with the main system using an application-specific socket protocol. The OPC module is developed with Delphi and Prosys Sentrol OPC UA & Classic SDK for Delphi, whereas the rest of the Valmet system is developed in .NET.

“Prosys OPC is a strong technological partner for us in the OPC field”, says Mr. Tapio Mattila, R&D Project Manager of Machine Vision Control & Measurement Solutions/ Process Automation Systems at Valmet. “I appreciate their state-of-the-art OPC expertise and the extensive Sentrol library, which ensures high productivity in the systems development phase. Cooperation with them has been uncomplicated and flexible, and we have always obtained service within very reasonable response time in our situation-specific needs”, he continues.

OPC technology enables the system to be connected to any major automation system with standard configuration. The software components of Prosys Sentrol OPC UA & Classic SDK for Delphi take care of numerous details required by reliable, interoperable OPC client and OPC server applications. Attention has been given to reliability and robustness to ensure that the OPC module can be used in continuous 24/7 production environments.

I appreciate their state-of-the-art OPC expertise and the extensive Sentrol library, which ensures very high productivity in the systems development phase.

Tapio Mattila

Valmet

Management of Intelligent Valve Controllers

Implementation

Prosys OPC has designed and developed ValveViewer, a Windows application for management of intelligent valve controllers, according to the requirements of Valmet. The implementation is based on Delphi and Prosys Sentrol, a leading SDK (software development kit) for OPC client, server and application development. Other tools that have been used include ModelMaker for UML, FinalBuilder, InstallShield and CVS for version control.

During the active development phase, agile methods were used in a seamless joint-operation. Extensive testing was performed both at development lab and on-site to ensure integration with automation systems from different vendors. ValveViewer quickly achieved acceptance as a productive tool for professionals of field devices and instrumentation, and is used in numerous installations worldwide. The software is currently in maintenance and support phase, where small enhancements and updates are made according to customer needs.

ValveViewer is a Windows application for management of Neles ND9000F series of intelligent valve controllers (and thereby also valves) connected to FOUNDATION fieldbus. The software is used during all main life cycle phases: commissioning, operation and maintenance.

ValveViewer provides a graphical user interface for configuration, monitoring, calibration, diagnostics and testing purposes. Advanced features of the software are based on the Neles valve controllers’ unique ability to store information from the valve’s entire life cycle in its memory, from where valuable valve performance and predictive diagnostics data can be retrieved.

ValveViewer includes an OPC client which connects to different OPC servers and reads information from devices of ND9000F series. Upon startup, the software scans available devices from the factory network (available from the OPC server), shows the device list for the user for device selection and opens the diagnostic interface for the selected device. Alternatively, the application can be launched directly for a selected device, which enables smooth integration with other systems and significantly improves usability.

Using smart adaptive algorithms ValveViewer can use information from OPC servers of various FOUNDATION fieldbus compatible automation systems such as Valmet, ABB, Emerson, Honeywell, Yokogawa and National Instruments. All things considered, ValveViewer offers a unique set of beneficial features to valve maintenance & engineering.

Prosys OPC has provided us with software experts and tools with a long-term commitment. In our projects, specification work is very important, yet it is difficult to get all requirements and details written in advance. This challenge was addressed by using agile methods, which produced good results. Another important factor was the demanding work required to achieve interoperability between different systems. Overall, I rate Prosys OPC services as praiseworthy and professional.

Pasi Heikkinen

Valmet