IoT & Field Connectivity Suite

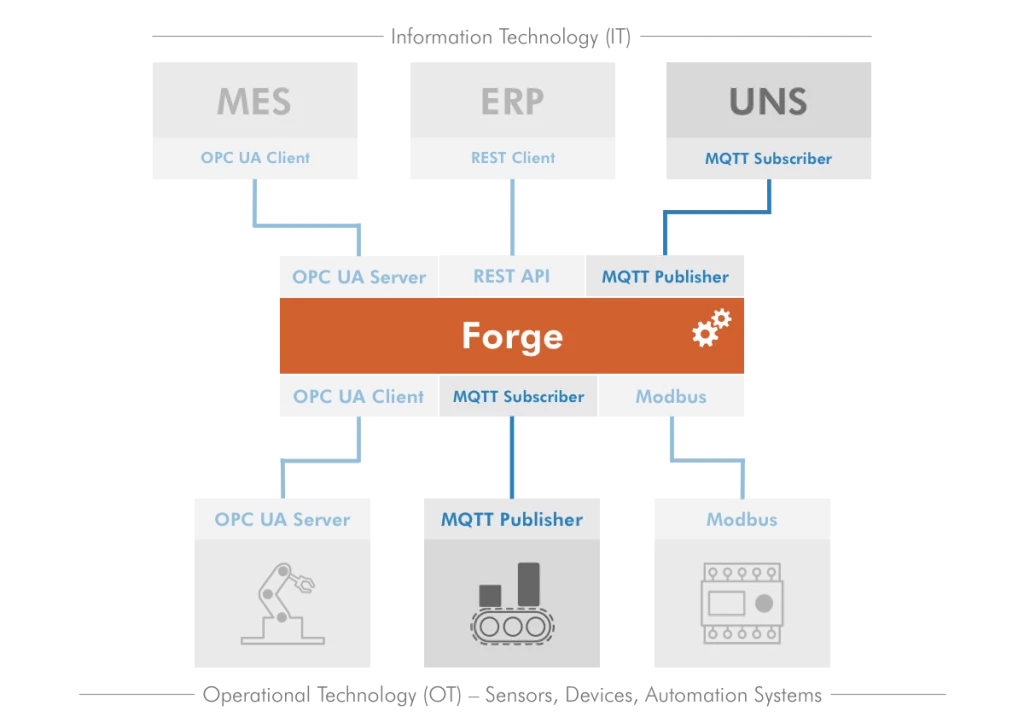

The IoT & Field Connectivity Suite in Prosys OPC UA Forge is designed to address the growing need for reliable and scalable communication between thousands of data sources, such as sensors and meters, especially over unreliable networks. This suite leverages the latest OPC UA PubSub communication model and customizable MQTT protocols to ensure efficient and flexible data transfer, making it an ideal solution for modern industrial applications.

Key Benefits

Flexibility

Reliability

Real-Time Communication

Main Features

Customizable MQTT

MQTT is a lightweight TCP-based publish-subscribe message protocol. It is designed for connections with limited resources and unreliable networks. Compared to MQTT-based OPC UA PubSub, pure MQTT gives you more freedom in defining message payloads and topic trees. Forge’s MQTT module lets you publish data from underlying OPC UA servers via its MQTT Publisher component. Users can also receive MQTT messages via Forge’s MQTT Subscriber component and map the values into OPC UA nodes.

UNS (Unified Namespace) promotes a hierarchical data structure of the enterprise, sites, and areas down to the equipment level to allow all data within the enterprise to be centrally accessible from a single location. It is MQTT-based and uses MQTT topic trees to convey the data structure. Forge collects and represents all data from different sources in a single information model. The model can be described as UNS using the MQTT topic tree in Forge, which enables you to define your own UNS efficiently.

OPC UA PubSub

PubSub, the newly adopted communication model in OPC UA, is a key feature of OPC UA Forge. It includes a Publisher component that allows you to define various datasets containing nodes. The publisher then publishes the data in messages. These messages are distributed into a network where subscribers can listen to them and filter what they need, providing a flexible and efficient communication model.

OPC UA offers two distinct network types for PubSub: the UDP-based (brokerless) local network and the MQTT-based message queue broker. In the former, a Publisher sends messages using UDP Broadcast or Unicast, which can only be received and interpreted by OPC UA subscribers. In the latter, the messages are typically encoded into JSON format. Here, a publisher sends messages to a broker, which is responsible for receiving all messages, filtering them, determining the appropriate subscribers, and then sending the message to them, highlighting the role of the broker in this process.

If a user needs to connect thousands of data sources, such as small sensors or remote meters, over unreliable networks, the client-server model will impose scalability problems. OPC UA utilizes the PubSub model’s fixed resource management feature to address the scaling problems. MQTT-based PubSub is lightweight and flexible in unreliable networks. UPD-based PubSub enables fast communication with large amounts of data. Once deterministic and fast networks, like Ethernet TSN, are available, real-time communication can be achieved via OPC UA PubSub.

The MQTT-based PubSub is suitable for cloud communication. For example, a user’s device data can be published to the cloud for data analysis. UDP-based PubSub can be used for peer-to-peer communication between controllers and between controllers and HMIs.

Modules

MQTT

The MQTT Publisher module is used for publishing messages to one or more MQTT subscribers via brokers. By publishing data on MQTT topics, a publisher enables subscribers to promptly receive relevant information. Additionally, the MQTT Publisher module allows users to structure UNS topic hierarchy. Select a root Node and every variable underneath the root Node will be published.

The MQTT Subscriber receives messages from MQTT publishers and maps data into OPC UA nodes.

You can use either external or the internal MQTT Broker, which provides a configurable central intermediary that receives messages from publishers, filters them based on topics, and delivers them to subscribers.

OPC UA Publisher

OPC UA PubSub over MQTT uses MQTT as a transport layer, and follows the OPC UA PubSub specification, which provides standard payload structures, message encoding formats (e.g. UADP, JSON), and metadata for data semantics. A publisher collects values of OPC UA variables, wraps the DataSetMessages into a PubSub NetworkMessages and transmits them over MQTT.

OPC UA PubSub over UDP transmits data from a publisher (typically a sensor, PLC, or server) to subscribers over UDP multicast or unicast. A publisher publishes DataSetMessages over a specified multicast or unicast UDP address. The messages are encoded using UADP format.

OPC UA Subscriber

A MQTT subscriber connects to a MQTT Broker and subscribes to MQTT Topics. It receives and decodes MQTT Messages to extract the payloads containing timestamps, values, status codes, etc.

A UDP subscriber subscribes to the same UDP address and port, and filters messages by Publisher ID, DataSetWriter ID, or MetaData.

FAQ

1. What does IoT & Field Connectivity Suite do?

It enables you to build a reliable and scalable communication network between an enormous number of devices and systems.

What is the difference between MQTT module and OPC UA PubSub over MQTT modules?

MQTT itself does not define the payload format. A publisher sends a byte array under a topic, and subscribers interpret it in whichever way they want. OPC UA PubSub over MQTT structures data according to the OPC UA information model and provides rich OPC UA semantics.

Events Suite

Despite these advantages, many industrial automation systems have OPC UA servers and clients that don’t support events. The Event Suite acts as an event enabler for such clients and servers, allowing them to generate and subscribe to events. This suite contains two modules: Event Generator and Event Mapper.

Real-Life Challenges

Manual Monitoring and Delayed Reactions

Manufacturers often receive OPC UA ready-made servers and clients that do not support events. In these servers, users can only find folder objects and variables. In the clients, only Data View is available. Without event support, users must manually monitor vast amounts of data to identify issues, leading to delayed reactions and potential downtime.

Limited Customization and Visibility

Without event support, users cannot define or subscribe to custom events, limiting their ability to track specific conditions or milestones. This lack of customization can hinder the efficiency and responsiveness of the system.

Solution

Forge’s Event Suite is an ideal extension for OPC UA servers and clients that do not support events. It enables users to fully benefit from the functionality provided by OPC UA events, transforming the way they monitor and respond to system conditions. By reducing the need for constant data monitoring and enabling real-time event notifications, users can quickly locate issues and take prompt action, improving overall system efficiency and reducing downtime.

Key Benefits

Improved Reaction Time

Real-time event notifications enable quick identification and response to issues, minimizing downtime.

Increased Efficiency

Reduce the need for constant data monitoring and focus on crucial information and reporting.

Customization

Tailor event notifications to specific needs, enhancing system monitoring and control.

Modules

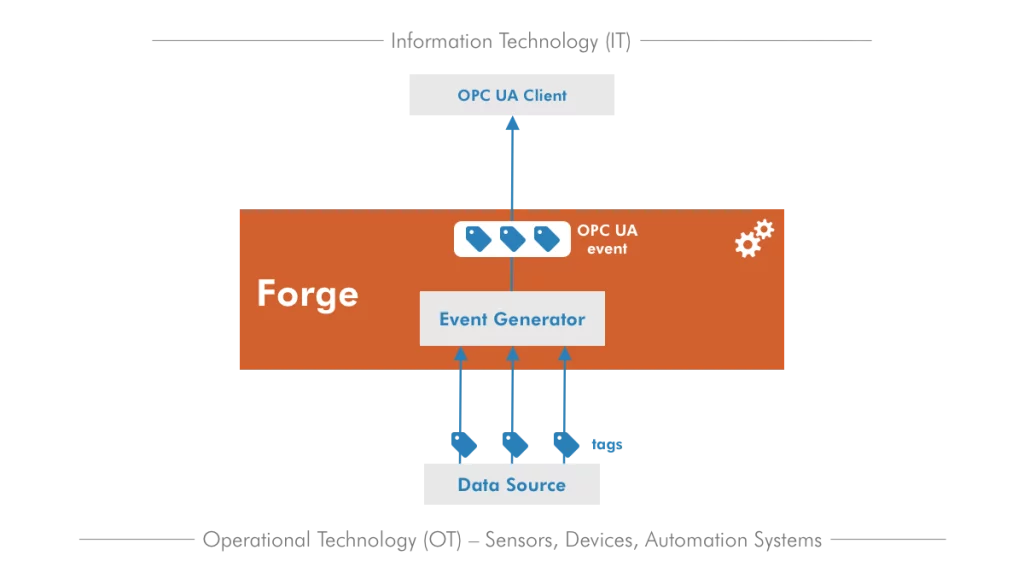

Event Generator

Combine Data Points into Events: Users can fully utilize customized information models to create self-defined events. They can import their own information models (in XML format) containing specific event types and create new events with custom templates. Users can define event properties such as message, severity, and time, tailoring the event notifications to their needs.

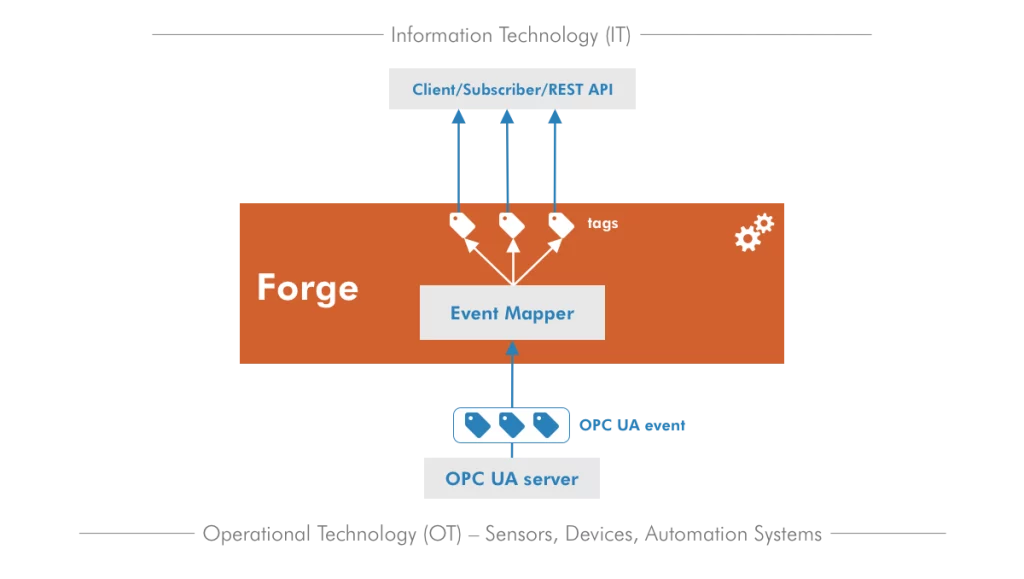

Event Mapper

Split Events into Data Points: This module allows users to view OPC UA event fields in Data Access/View from an OPC UA Client. It enables users to configure how events are collected, processed, and exchanged, facilitating real-time data flow and synchronization. Users gain better visibility and control over the events, enhancing their ability to monitor and respond to critical conditions.

FAQ

1. What types of events can be generated with the Event Suite?

Event Suite allows users to create custom events based on their specific requirements. Users can define event properties such as message, severity, and time, tailoring the events to their needs.

2. Is the Event Suite compatible with all OPC UA servers and clients?

Event Suite is designed to be compatible with most OPC UA servers and clients, enabling them to support event generation and subscription even if they initially do not.

3. How does the Event Suite improve system efficiency?

By providing real-time event notifications and reducing the need for constant data monitoring, the Event Suite helps users quickly identify and respond to issues, improving overall system efficiency.

4. Can I import my own information models into the Event Suite?

Yes, users can import their own information models in XML format, allowing for the creation of self-defined events tailored to their specific requirements.

5. What kind of support is available for Event Suite implementation?

We offer comprehensive support including documentation, tutorials, and customer service to assist with the implementation and use of the Event Suite.

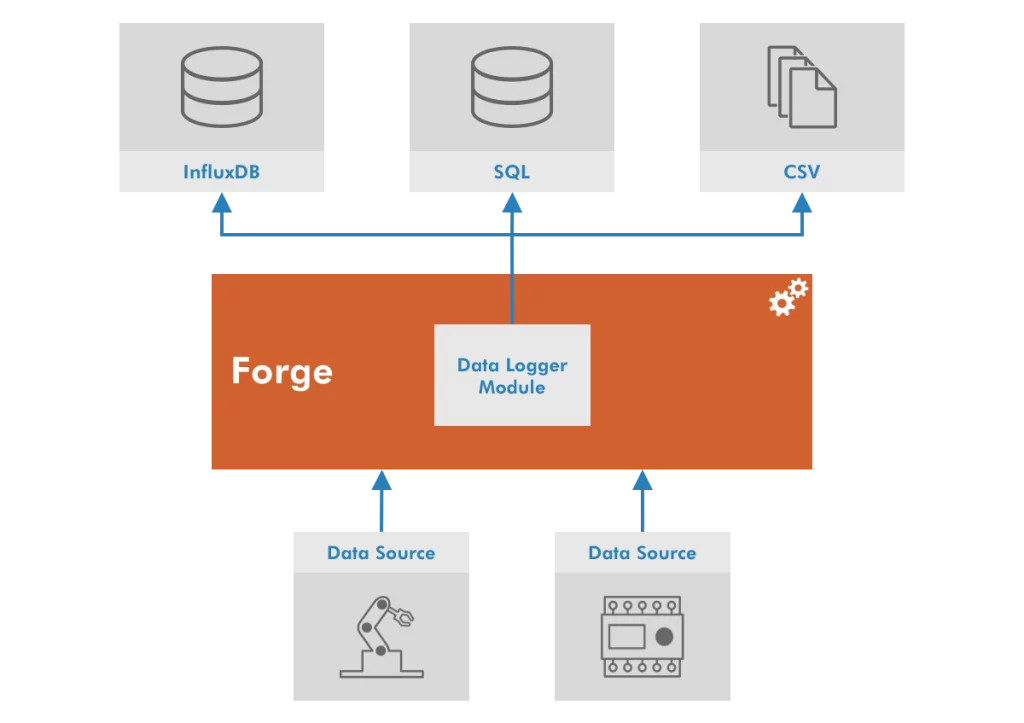

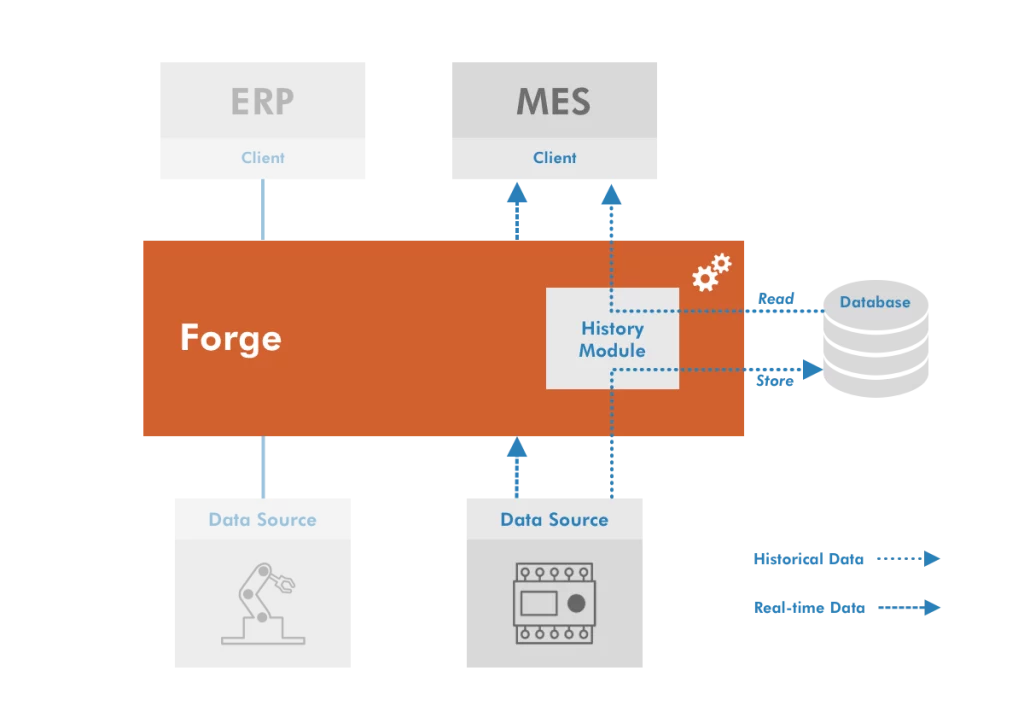

Data Storage Suite

Efficiently manage and utilize your historical data with the Data Storage Suite. This suite offers a standardized approach to storing, accessing, and analyzing data from various sources. By logging data into databases and CSV files, you can perform in-depth performance analysis, fault diagnosis, and reporting. Optimize processes, improve maintenance efficiency, and ensure product quality through effective data storage and retrieval.

Real-Life Challenges

Analyzing Historical Data

Historical data is crucial for understanding how vital process variables, such as power consumption, temperature, or pressure, change over time. Without a proper data storage solution, it becomes challenging to identify trends and patterns that are essential for optimizing processes, identifying potential problems, and ensuring product quality.

Preventing Downtime

Early identification of equipment failure is vital to prevent costly downtime and improve maintenance efficiency. Without historical data analysis, detecting early signs of issues that could lead to significant operational disruptions is difficult.

Solution

The Data Storage Suite provides a standardized way for different software applications to access and utilize historical process data, regardless of the source or platform. This suite logs data from various sources into databases or CSV files. The logged data in a variety of formats enables management-level actions such as performance analysis, fault diagnosis, and reporting. This suite allows you to optimize processes, enhance maintenance efficiency, and ensure product quality through effective data analysis.

Key Benefits

Standardized Data Storage

Provides a consistent way to store historical data, making it easily accessible and usable across different platforms and applications.

Efficient Reporting

Enables the generation of detailed reports based on historical data, supporting informed decision-making.

Efficiency & Optimization

Facilitates the analysis of historical data to identify trends, patterns, and faults, which is crucial for process optimization and maintenance efficiency.

Modules

Data Logger

Collect Data: Logs data from various sources to local databases (SQL, InfluxDB) and archives (CSV files) for future analysis and reference. You can create data sinks for different databases and create profiles to define the formats in which the data is stored.

This way, you can ensure compatibility with different analysis tools and applications. You can tailor the data storage process to meet your systems’ specific needs.

History

Enable Historical Data: Logs real-time data into InfluxDB with a fixed standard profile and retrieves historical data upon an OPC UA client’s request. This means that the current and historical data can be accessed from the same OPC UA node, even when the original data source only provides real-time values.

FAQ

1. What is the Data Storage Suite?

It is a Forge suite that provides a standardized way for you to store, access, and utilize historical process data, regardless of the source or platform. This data is stored in databases or CSV files for common uses like performance analysis, fault diagnosis, reporting, etc.

2. What kind of challenges would I solve with the Data Storage Suite?

Data Storage’s main purpose is to add data collection or logging to systems that do not inherently support them.

3. What does the Data Logger do?

The Data Logger module logs data from various sources to databases (SQL, InfluxDB) and archives (CSV files) for future analysis and reference. You can create data sinks for different databases and create profiles to define the formats in which your data is stored.

4. What does the History Module do?

The History Module logs data into InfluxDB with a fixed profile and then enables users to retrieve the stored data via OPC UA client applications with Historical Access.

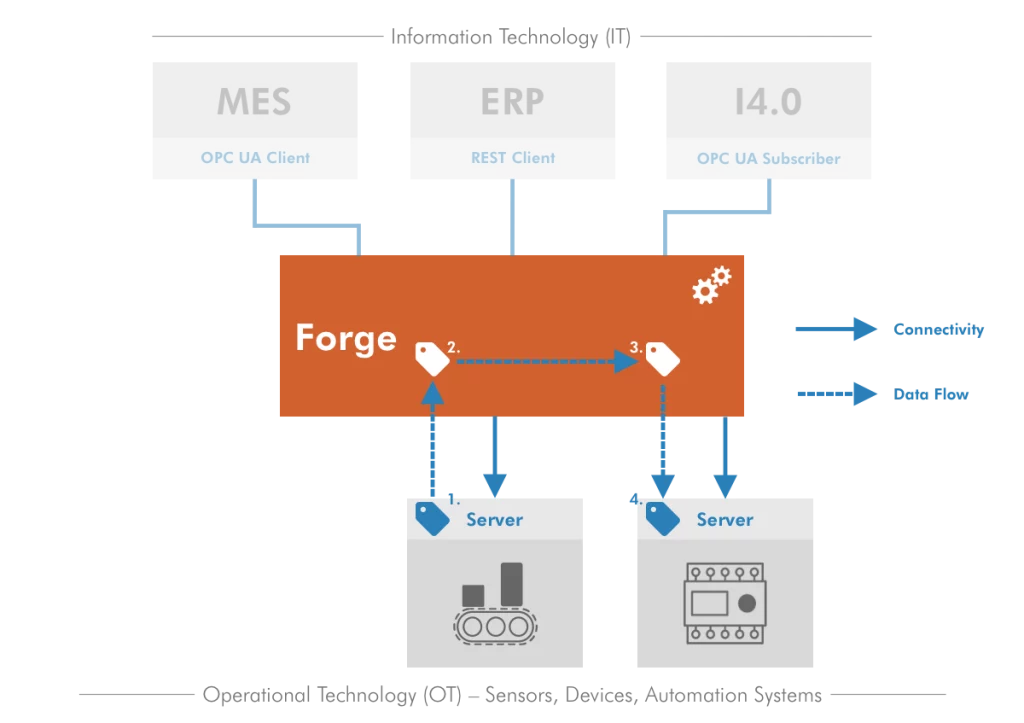

Data Exchange Suite

Facilitate seamless data communication between different OPC UA servers with the Data Exchange Suite. This suite enables data transfer between systems, ensuring smooth synchronization and enhanced connectivity. Perfect for environments with multiple devices and systems, the Data Exchange Suite helps you reduce manual monitoring, minimize data inconsistencies, and improve overall system efficiency.

Real-Life Challenges

Limited Direct Communication

Many devices and systems are equipped with only OPC UA servers and not clients. At the same time, they are required to communicate in specific use cases. For example, suppose a PLC (with a UA server) needs to receive data from another similar device. In that case, it cannot receive the data because two OPC UA servers are not inherently capable of communicating with each other. This challenge is common in industrial environments where communication between servers is needed.

Interoperability Issues

Different systems and devices may face interoperability issues when not all of them are communicating through the same protocols. Without a proper data exchange solution, it is difficult to synchronize data and maintain efficient operations. This can lead to an increased need for manual monitoring, data inconsistencies, and inefficiencies.

Solution

The Data Exchange Suite is designed to address these challenges by enabling seamless server-to-server communication within the OPC UA framework. This suite allows you to read values from nodes in one server and write these values to nodes in another server. This way, you will have smooth data transfer and synchronization across different devices and systems. Integrating this module allows you to ensure efficient data flow, reduce manual intervention, and enhance system interoperability.

Key Benefits

Enhanced Connectivity

Enables seamless communication between OPC UA servers, ensuring data consistency and synchronization.

Increased Efficiency

Reduces the need for manual data handling and monitoring, allowing users to focus on critical tasks.

Interoperability

Facilitates communication between devices and systems, enhancing overall system performance.

Modules

Exchange

Real-Time Server-Server Communication: The Data Exchange module reads values from nodes in one server and writes these values to nodes in another server. This enables efficient data exchange and synchronization between different systems.

You can define specific data exchange processes, ensuring critical data is consistently and accurately transferred between systems in real time. This enhances overall system responsiveness and reliability.

FAQ

1. What is Data Exchange?

Data Exchange is a Forge Suite that enables server-server communication between devices and systems.

2. How does the Data Exchange Suite improve system efficiency?

It enables seamless data transfer between different systems. This, in turn, reduces the need for manual intervention, minimizes data inconsistencies, and enhances overall system efficiency.

3. Can I customize the data exchange processes within the suite?

Yes, you can define specific data exchange processes tailored to your needs, ensuring optimal integration and functionality.

4. Is the Data Exchange Suite compatible with all OPC UA servers?

Yes, the suite is designed to be compatible with all OPC UA servers, facilitating broad interoperability.

5. Does the Data Exchange Suite support communication between non-OPC UA servers?

Data Exchange Suite can be used with Connectors to get data from non-OPC UA servers (like Modbus, Beckhoff ADS, and Siemens S7comm) into the Forge. Then, you can use Data Exchange to write these values to your target nodes.

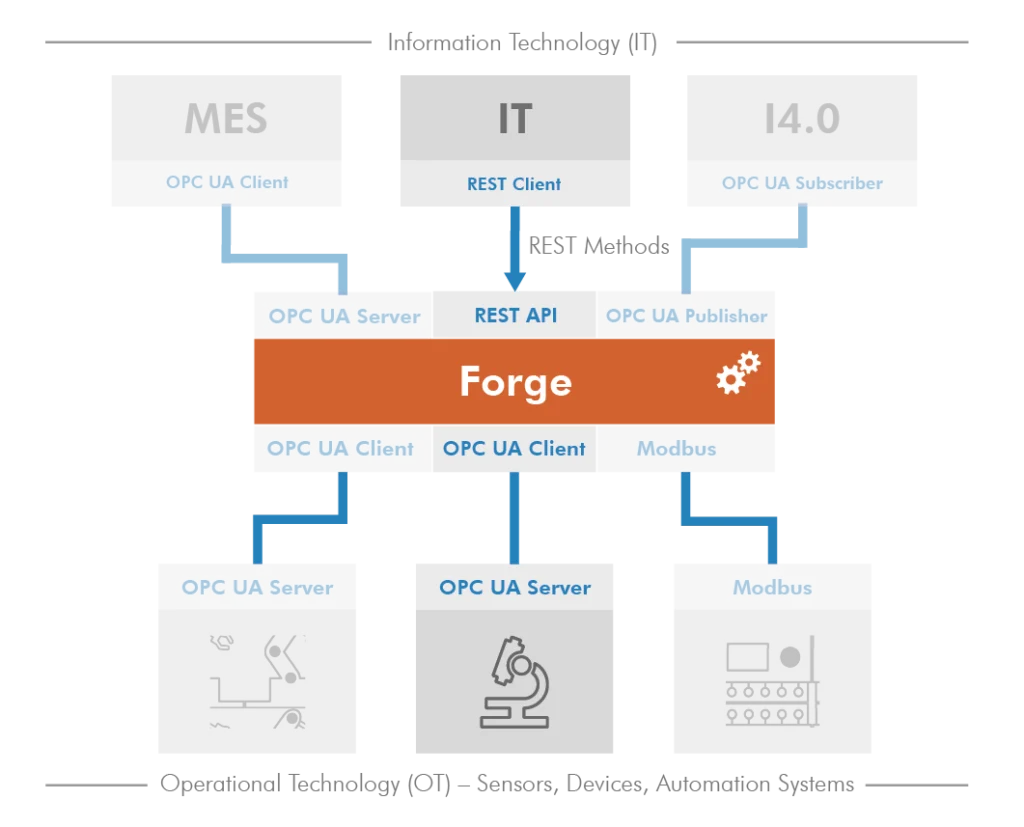

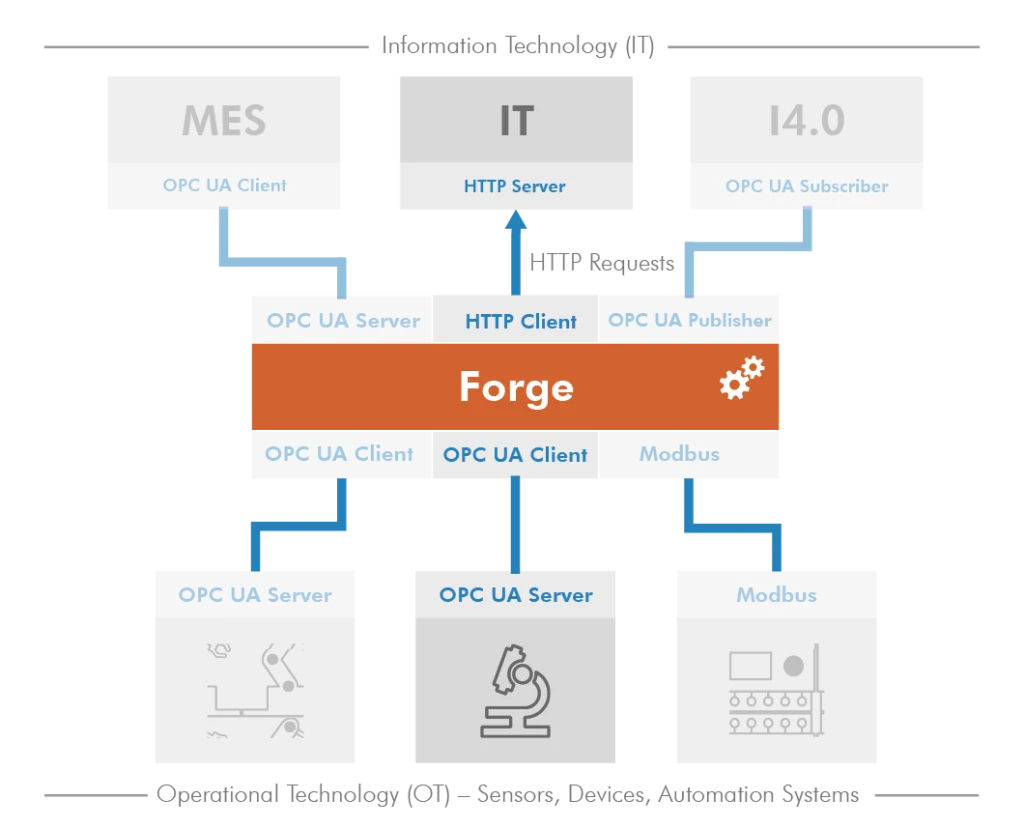

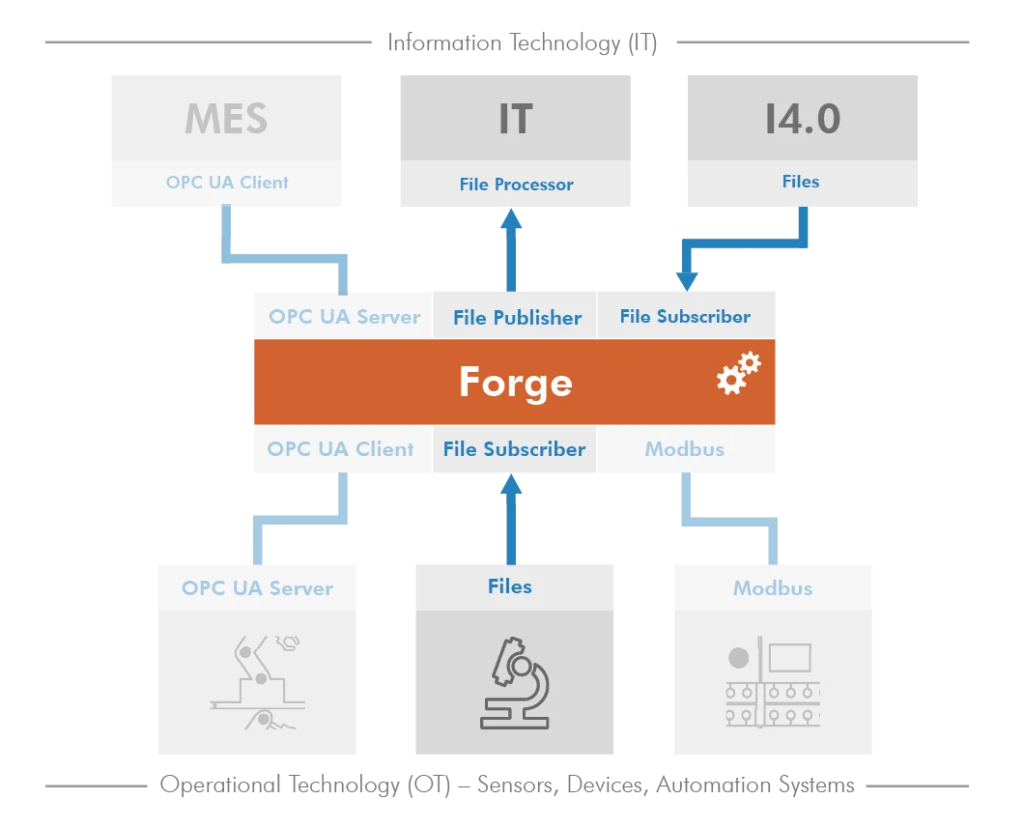

HTTP Connectivity Suite

REST APIs are commonly used in cloud platforms, databases, ERP/MES, and analytics tools. OPC UA is used by PLCs, SCADA systems, and industrial controllers. Forge’s HTTP Connectivity Suite bridges them to facilitate horizontal IT/OT integration.

Real-Life Challenges

Exposing OT data with REST

Many enterprise and cloud systems don’t support OPC UA natively. Instead, they use REST which is stateless and fits well into cloud-native and microservices architectures. How to retrieve OPC UA data using a REST client?

Custom HTTP requests imposed by different Web services and APIs

Solution

HTTP Connectivity Suite allows users to use standard REST methods to access OPC UA services. Additionally, it allows users to customize HTTP requests according to the specifications provided by REST service and API providers. Thus, this suite facilitates the interaction between device data and web-based services.

Key Benefits

Simplified Configuration

Allows users to configure Forge using standard REST methods, streamlining the setup and management processes.

Makes real-time machine data accessible over REST for dashboards, analytics, or AI applications. Forge exposes only selected data points via a REST interface, reducing attacking surface.

Flexible Data Formats

Supports JSON and XML data formats, ensuring compatibility with a wide range of applications and systems.

Modules

OPC UA over REST

Enables users to interact with OPC UA services through a RESTful API which performs various OPC UA operations via standard REST methods. Addition to reading and writing data, this module simplifies complex setups and configurations like importing multiple connections and modifying a big number of nodes.

HTTP

Enables seamless integration with various web services and APIs by enabling users to send fully customizable HTTP requests. Users can easily define request headers and bodies, and dynamically link values from underlying OPC UA servers to specific parts of the request and the response. This flexibility simplifies the process of connecting your OT data to web-based systems and services.

FAQ

1. What does OPC UA over REST do?

OPC UA Forge with built-in REST APIs enables users to use familiar REST methods (like GET and POST) with JSON or XML data formats to configure Forge (especially for the containerized Forge edition) and access data from source servers.

2. Does OPC UA over REST require me to already be using OPC UA?

Yes, the idea is to enable REST APIs in customers’ systems to access data in existing OPC UA servers via standard REST methods. This integration leverages existing OPC UA infrastructure to provide RESTful access to data.

What does HTTP module do?

The Forge HTTP module allows users to send customized HTTP requests to interact with servers, enabling both data retrieval and data transmission.

Advanced Mappings Suite

Operational systems and data analysis tools often require combining individual pieces of data into larger, summarized datasets to spot trends, track equipment performance, and make informed decisions. Feeding unprocessed data into these tools can be inefficient and may not provide any actionable insights.

Advanced Mappings enables you to modify and even apply complex logic to the data, preparing it for analysis or other purposes, thereby enhancing the overall efficiency and effectiveness of data utilization. This is useful when the mapped data needs to be modified, for example, in unit conversion or when correcting systematic errors.

Modules

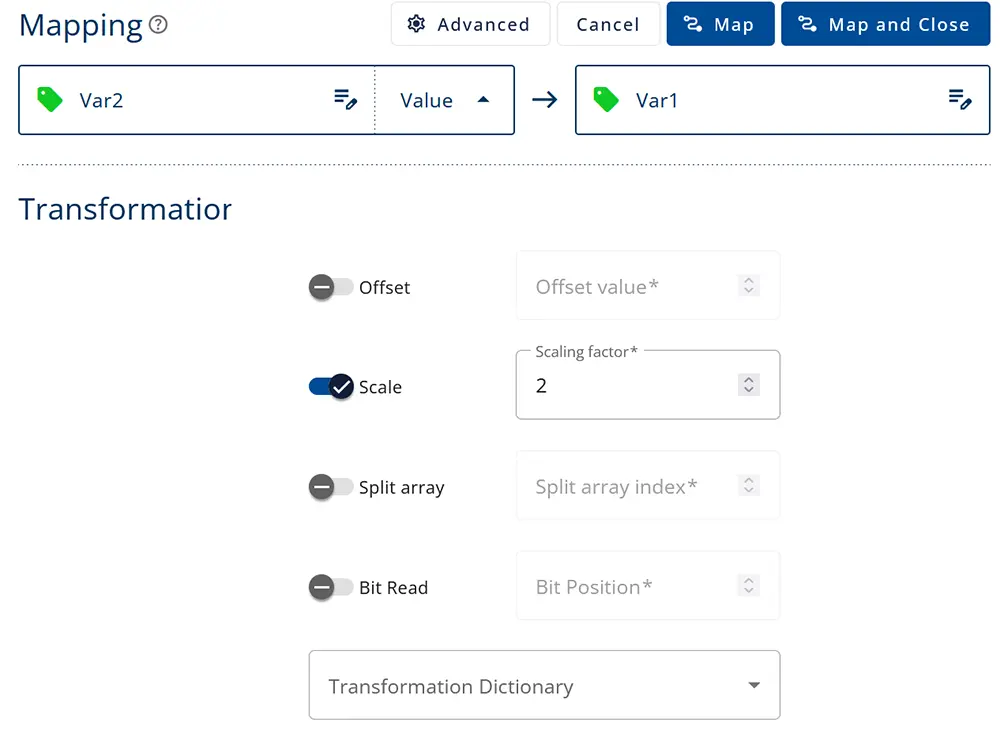

Mappings

Offset: Adds the offset value to the mapped value.

Scale: Multiplies the mapped value by the scaling factor.

Split Array: Selects the scalar value from the mapped array located in the index.

Bit Read: Reads if the selected bit from the mapped value is 0 or 1. Position 0 refers to the least significant bit.

Transformation Dictionary: Converts selected source values into target values.

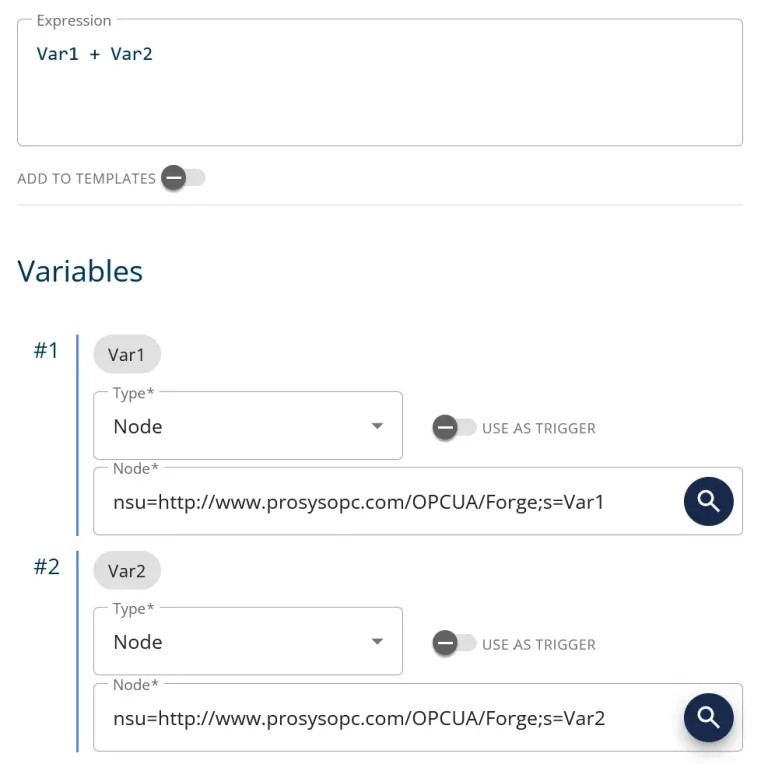

Expressions

With this feature, you can write conditional statements and use values from multiple nodes using JEXL programming syntax. Updating the output value of the Expression is done every time a trigger is activated. The user can define certain conditions or changes of address space variables to act as triggers for the Expression. A simple example of an Expression would be to sum two variables together.

FAQ

1. What does Advanced Mappings do?

It enables you to modify data in real-time and even apply complex logic, thus serving operational systems and data analysis tools effectively.

File Suite

File suite enables reading and updating data from/to various file formats and integrating data into the OPC UA address space. Supported file formats include JSON, and XML and supported file locations are local directories, FTP, SFTP and SMB. Use Files to map data from files into the OPC UA address space or vice versa.

You can easily configure connections to file transfer servers. Alternatively, you can use local file system. Templates feature allows you to create reusable templates for File Publishers and Subscribers to use.

Key Benefits

Simplified Configuration

Interoperability

Flexible Data Formats

Modules

File

File Publishers allow sending JSON/XML formatted files to the location defined in the File Connections. The content of the files can be configured by using values from the OPC UA address space.

File Subscriptions are used to read files, and mapping their content to the OPC UA address space.

FAQ

1. What does File Suite do?

It enables file-based data integration with OPC UA. It reads, writes, and updates JSON or XML files via local directories or FTP, SFTP, and SMB connections, linking file data directly with the OPC UA address space.