Prosys OPC UA Forge

Control, Secure, and Integrate Your Data with Ease.

Why Prosys OPC UA Forge matters for industrial connectivity

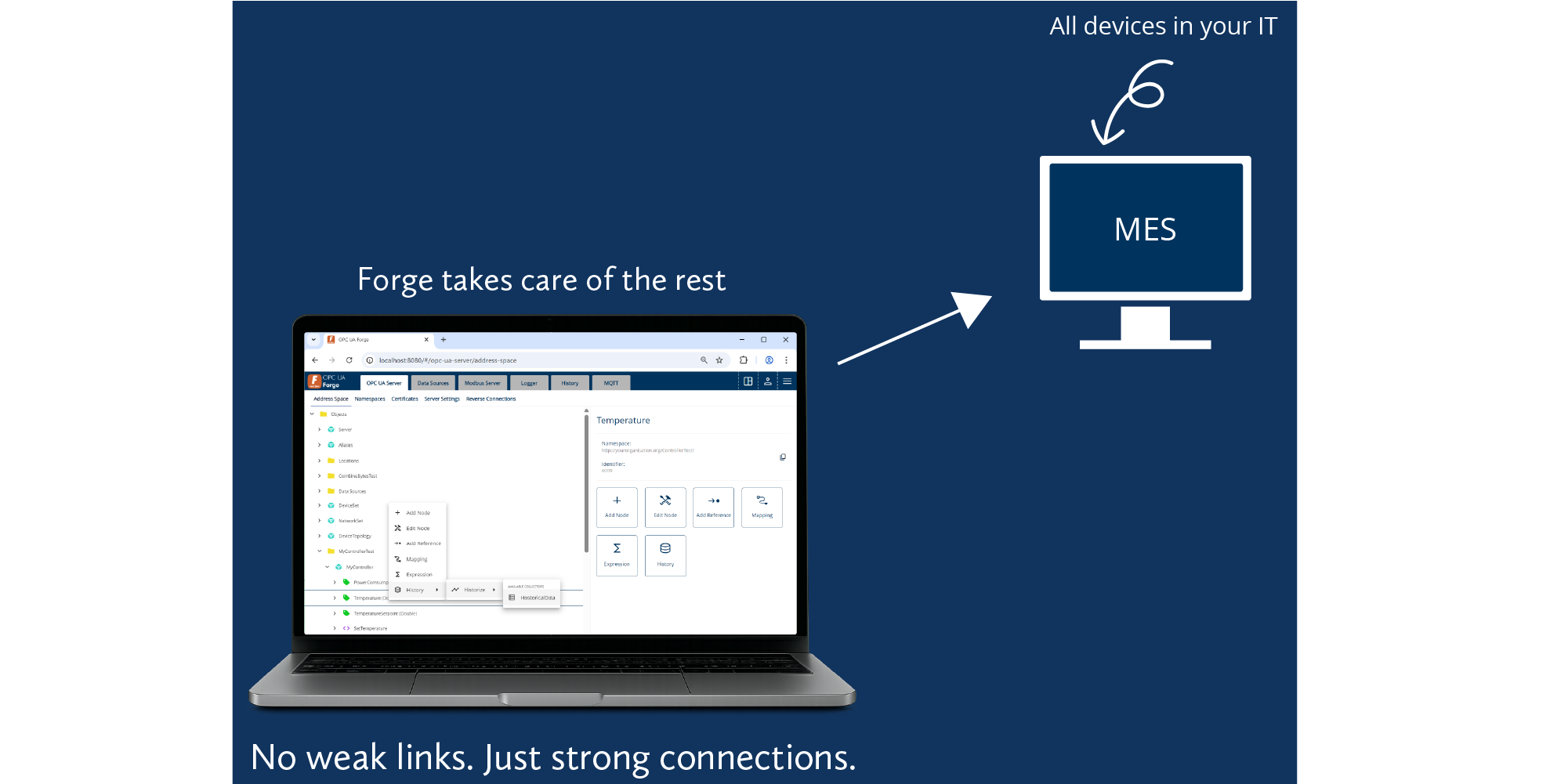

Prosys OPC UA Forge is a highly scalable Industrial DataOps and IT/OT integration platform to enable smooth and secure integration of industrial devices, machines, and sensors to industrial and generic IT and cloud systems. The core of the Forge is the OPC UA server, which supports the use of standard information models for data harmonization. The suites and connectors enable the use of most common industrial protocols, generic IT protocols such as REST and MQTT/UNS, together with advanced business logic operations.

Key Benefits

Unified Industrial Data Modeling

Learn more

Easily model, organize, and unify your industrial data using OPC UA. Forge makes your raw data meaningful, ready for advanced analytics, dashboards, and connected systems.

Faster Time to Integration

Learn more

Connect to your machines and systems in minutes, not weeks. Whether it’s OPC UA Servers, PLCs, or enterprise systems, Forge simplifies and speeds up integration without custom code.

Built for Engineers, Loved by IT

Learn more

Designed for automation experts, with the structure and security IT requires. No need to compromise, Forge bridges operational know-how with modern IT architecture.

Proven Security and Control

Learn more

Secure by design with granular control over data flow. Keep your operations safe with OPC UA’s built-in security, access control and encrypted communications.

Scalable from Pilot to Production

Learn more

Start small. Scale fast. From one machine to hundreds of systems, Forge adapts to your needs as you grow.

Vendor-Neutral & Future-Proof

Learn more

No lock-ins, just standards. Built on OPC UA and optional Connectors, Forge ensures interoperability and long-term sustainability.

Ready for Analytics, AI, and Cloud

Learn more

Get your data where it needs to be, clean, structured, and contextual. Forge is the ideal foundation for dashboards, performance optimization, and enterprise data lakes.

Real Results from the Factory Floor

With Prosys OPC UA Forge, we were able to easily integrate various PLCs and devices into our database and visualize data in real time on Grafana dashboards. The entire process, from configuring devices to monitoring production, was smooth and efficient, making this tool indispensable for our factory operations.

Automation Engineer

Casa Mendes Gonçalves

i-GuSystem improved scalability and ensured future-readiness by using Prosys OPC UA Forge for seamless CNC data integration and reliable system compatibility.

“I expected the first install might take a full day, maybe two. I left the site in just two hours, everything working as planned. That’s rare in this business.”

CEO

i-GuSystem Oy

Valio Connected Dairy Plant Automation and IT with Prosys OPC UA Forge.

The Prosys OPC UA Forge deployment project was carried out exactly according to plan, both in terms of costs and schedules. During the co-operation we have found out that Prosys OPC UA Forge is a versatile product, capable of executing secure IT/OT integration in all our production sites and extending to cloud-based systems. We always prefer forward-looking and reliable suppliers that properly understand production environments, and Prosys OPC fully meets our requirements.

Service Manager

Valio

Get started with Forge today

Request a demo or get in touch with our experts.

Your Needs Are Important

Our Support Team is here to help you succeed, quickly, reliably and with deep technical expertise. We listen, solve and support, because your needs truly matter.

What can You Do with Forge?

Forge gives you all the tools to model, map, store and move your industrial data — securely and at scale.

Suites

Suites include one or more technical modules designed to meet the advanced requirements of various use cases.

Connectors

Connectors enable native communication between Forge and industrial devices such as PLCs and RTUs, using selected widely adopted protocols. These include Modbus, Ethernet/IP (commonly used with Rockwell and Omron devices), ADS (for Beckhoff devices), and S7 (for Siemens S7 PLCs). SQL connector enables mapping database queries to OPC UA address space.

Free & Useful

The Forge Grafana Plugin brings OT data from Prosys OPC UA Forge into IT dashboards via the popular open-source dashboarding platform Grafana. It enables you to visualize both real-time and historical OT data directly. If your original data source lacks historical data, you can easily configure Forge to store it, allowing you to fully leverage the capabilities of the Plugin.

Mastering Forge Tutorial Series

Learn how to get the most from Forge with our step-by-step tutorials and real-world examples.

Related Blog Posts

Technical Details

- Windows

- Linux

- Docker

- Main Features

- Data Access

- History Access

- Events

- Methods

- OPC UA over REST

- Import NodeSet2.xml models

- Reverse Connect

- Client-Server

- OPC UA TCP (OPC UA Binary)

- PubSub

- MQTT (UADP, JSON)

- OPC UA UDP (UADP)

- Security Policies

- Aes256-Sha256-RsaPss

- Aes128-Sha256-RsaOaep

- Basic256Sha256

- Basic256 *

- Basic128Rsa15 *

- * Deprecated in OPC UA specification, provided for compatibility with older systems

- Supported Versions

- 1.05 and earlier

- Modbus TCP, RTU, RTU/TCP, ASCII

- Automation Device Specification (ADS)

- Siemens S7comm

- EtherNet/IP

- MQTT

- HTTP

- FTP, SFTP, SMB (JSON, XML)

- InfluxDB

- MySQL

- MariaDB

- Microsoft SQL Server

- PostgreSQL

- Oracle

- Current Release: 1.5.4

For more information, please see the Release Notes - Version 1.X

- Subscription for Single Installation

- Subscription for Site Installation

- Perpetual License for Single Installation

- Perpetual License for Site Installation

Please note that a Core license needs to be in place before any Suite or Connector licenses can be activated. Evaluation licenses are available upon request.

Get started with Forge today

Request a demo or get in touch with our experts.