Industry 4.0 and Open Standards: How OPC UA, WoT, i3X, and MQTT Build a Functional Architecture

Definitions

- OPC UA: The foundation for industrial interoperability. It’s not just a protocol but a framework for structured data exchange with built-in information modeling and semantics.

- Web of Things (WoT): A W3C standard for describing device capabilities. Through the OPC UA Companion Specification, WoT descriptions can be integrated directly into OPC UA models to automate device onboarding.

- MQTT: A lightweight pub/sub messaging protocol. In an OPC UA context, it serves as a transport mechanism (PubSub) for distributing structured data to cloud and event-driven systems.

- CESMII i3X: A REST-based framework for discovering and querying industrial metadata. It simplifies web-based access to OPC UA information models.

- Unified Namespace (UNS): Not a technical standard, but an architectural mindset. It’s about organizing plant-wide data into a logical structure. While often associated with MQTT, it requires a semantic backbone, in principle, OPC UA, to be scalable.

Moving Beyond Data Transport

The vision of Industry 4.0 has been around for over a decade, but most factories are still stuck with isolated data silos and point-to-point integrations. Moving data from a machine to an IT system isn’t new; I’ve been doing that for 30 years. The real challenge is building an architecture that scales through automated onboarding, reliable operations, and secure exchange between OT and IT.

Recently, the Unified Namespace (UNS) has gained traction. Early interpretations often focused narrowly on publishing ISA-95 structured data to an MQTT broker. For me, this wasn’t particularly interesting because it didn’t solve the core issues of real Industry 4.0 adoption.

However, the conversation is maturing. UNS is increasingly seen as part of a broader service-oriented architecture that integrates multiple standards. This shift makes the discussion relevant, as it finally addresses the practical requirements of a scalable system.

Core Requirements for a Service-Based Architecture

Based on my experience in integration projects, a functional Industry 4.0 architecture must meet these five criteria:

- Continuous Data Availability: Systems need access to the current state of the process at all times, not just when a value changes and all this in a logical, standardized hierarchy.

- Standardized Semantics: Raw data is useless without context. Metadata must automatically describe units, meanings, and relationships.

- Automated Onboarding: “Plug-and-produce” remains rare. We need to reduce manual engineering when adding new devices.

- Standardized Discovery: IT systems should be able to query the available data without manual configuration or custom integration code.

- Security by Design: Authentication and encryption must be built into the communication layer, not treated as an afterthought.

Mapping Standards to Requirements

We don’t need to wait for new technologies; the building blocks already exist. The key is how we combine them.

OPC UA as the Semantic Backbone. An aggregating OPC UA server using standardized information models (from OPC Foundation or CESMII) provides a single point of truth for harmonized data. It fulfills the need for structure and semantics that simpler protocols lack.

WoT and i3X for Automation and Discovery. The Web of Things (WoT) helps automate device onboarding by providing a standard way to describe a device’s capabilities. When combined with the CESMII i3X REST interface, it allows IT systems to discover and auto-configure themselves based on the available data models. This moves us from “integration projects” toward reusable system configurations.

The Real Role of MQTT: MQTT is often marketed as the solution for everything in UNS. In reality, MQTT alone lacks the structure needed for a complete Industry 4.0 architecture. However, it is excellent for event-driven data streaming. When you need to feed AI or cloud analytics with on-change data, publishing OPC UA way structured JSON payloads via MQTT is highly efficient. It complements the architecture; it doesn’t replace the need for a structured information model.

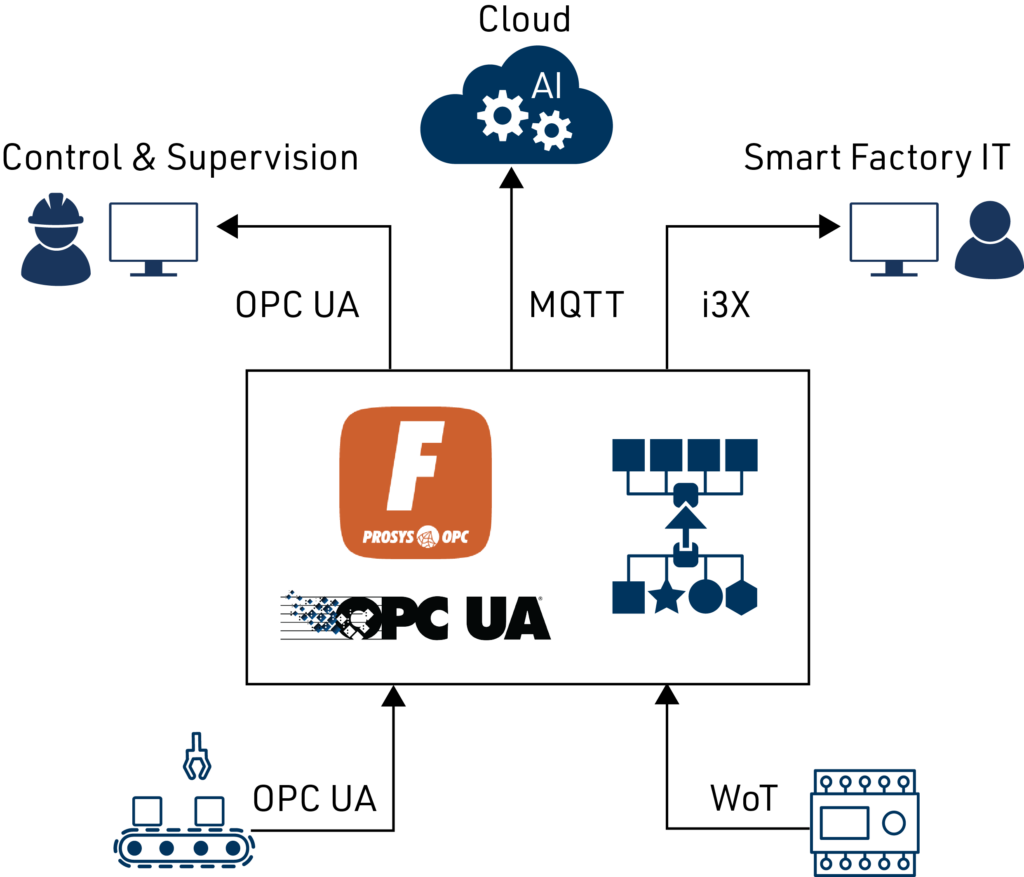

Configuration and data flows for Industry 4.0 OT/IT integration, with information modeling and data source aggregation.

Summary: Practical Implementation Over Hype

Real Industry 4.0 isn’t about picking one “winning” protocol. It’s about building a layered ecosystem where each standard does what it’s best at:

- OPC UA provides the structured foundation and security.

- WoT handles device abstraction and onboarding.

- i3X enables discovery and web-scale integration.

- MQTT handles efficient event distribution and cloud connectivity.

- UNS provides the logical organization for these services.

The technology is ready, and the standards are mature. The next step is to shift from merely transporting data to designing architectures that prioritize semantics and automation.

Our objective is to provide our customers with products and professional services to build modern Industry 4.0 systems. For example, Prosys OPC UA Forge is an easy-to-set-up IT/OT integration tool that implements most of the aforementioned features. In addition, our OPC UA SDKs are well suited to build your own customized Industry 4.0 solutions tailored to your specific integration requirements.

Pyry Grönholm

CEO

Email: pyry.gronholm@prosysopc.com