Why is Prosys OPC UA Forge an Important Part of Industry 4.0 Factory?

Introduction

It’s been more than 10 years since we started with our long-term service customer Valio. The goal of the project was to design the OT – IT integration of the modern factory. By then, no one spoke about industry 4.0 nor about Edge Devices and Computing. The main requirements were simple integrations and security. To meet this demand, our reference architecture included an application, which was aggregating OPC UA servers and provided a single point of access to all plant automation data. Since then, I have always recommended placing such in every factory.

Main Duties

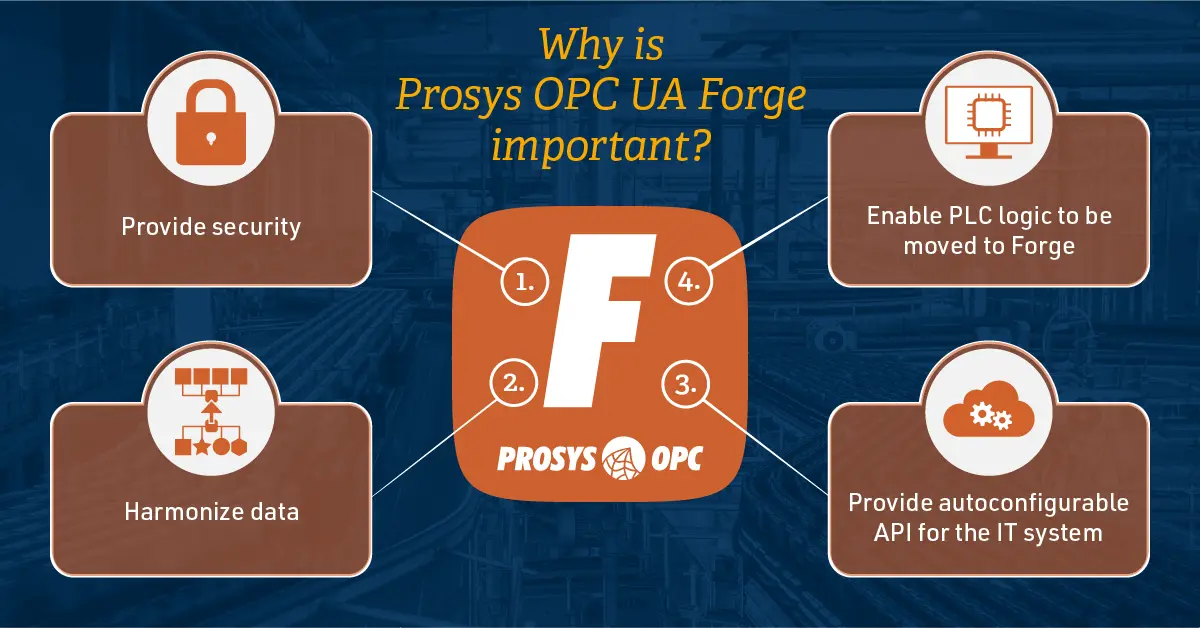

Nowadays, I see that the Edge application is, of course, much more than just an aggregating OPC UA server; actually, it is the main part of an Industry 4.0 factory. So, what are the main duties of the Edge application:

- Provide security

- Harmonize data

- Provide an easy/auto-configurable API for the IT system

- Enable PLC logic to be moved to the Edge application

Provide Security

Isolating the Automation network(s) from other networks is the key part of a secure Industry 4.0 setup. Placing an Edge application between the networks is an easy way to control all traffic between them from a single point. In the same way, you can define access control for different users in one single place.

Harmonize Data

To enable easy configuration and onboarding of machines, devices and IT systems; data of automation systems should be harmonised in such a way that all similar machines look the same from an information model perspective. The best approach is, of course, for the machines and devices to use natively standardised information models, but as this is yet to be a reality, the information must be converted to standard models. An Edge application is a natural place for such harmonisation, and when the harmonisation is made over there, the standard interface to device information is available for both Factory IT and Cloud IT.

Provide Easy/Auto Configurable API for IT System

We all know stories about failed IT system on-boardings where the overall complexity of the integrations was too high, and the way to success was to reduce the overall target to the absolute minimum. To overcome such issues, the Edge application has to provide standard interfaces. In practice, Industry 4.0 requires both OPC UA Server and Publisher interfaces that follow the best practice guidelines. This can enable plug & produce onboarding of devices to modern Industry 4.0 IT systems – which should also follow the standard specifications and guidelines.

Enable PLC Logic to be Moved to the Edge application

In many cases, the onboarding or leveraging of the coverage of the MES and other IT systems requires bigger changes than just data information modeling and naming. Making changes to the PLC and DCS code typically takes relatively much time and may cause downtime to the production. A good Edge solution also enables additional business logic to be defined. This could, for example, enable method calls and events to be converted to writing and reading PLC/DCS tags, respectively.

More Information and Testing

All the above requirements are committed to being solved in our just-released Prosys OPC UA Forge solution. Don’t hesitate to contact us by email at sales@prosysopc.com or through our website contact form. And since we are in active development mode, we will also be glad to hear your suggestions for further features or functionalities.

Author Info

Pyry Grönholm

CEO, Prosys OPC

Email: pyry.gronholm@prosysopc.com